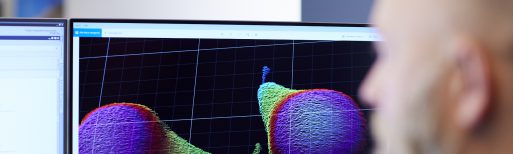

How our checkweighers work

The weight of the different samples that have been weighed by the checkweigher can be sent to the PLC (programmable logic controller) by means of a fieldbus, such as Profinet. This way, signal exchanges between machines in the front and in the back becomes perfectly possible. With a high line speed, all packets can be randomly weighed, both in shape and weight.

The junction box and the control panel are housed in the sheet steel housing of the checkweigher. This casing is also part of the frame. This creates a solid construction under the load cell, so that vibrations do not affect the weighing moments.

The checkweigher can be expanded with a rejector for products that fall outside the set over and under tolerance. In this way, the production line can continue to run. This prevents unnecessary standstill of the machines. It is possible to read the checked weight and store it in a database.

Use of our checkweighers

ARCO’s checkweighers can be used for boxes, bags, cans, jars, sachets and more. A checkweigher is an utmost useful and commonly used weighing machine, especially in the logistics sector and in the agri-food sector.

Advantages of our checkweighers

The benefits of an ARCO checkweigher are:

- ARCO is familiar in many production environments;

- Thanks to our experience, we always offer the best solution for your situation;

- Fast installation thanks to our extensive knowledge, which reduces the purchase costs;

- Training options, so that the maximum results can be obtained from every checkweigher and therefore from every production;

- Solutions for every budget;

- Also available in stainless steel or your own RAL color.

Other possibilities

Are you looking for a weighing solution for loosely packed products? Also take a look at our PM2020-HC or PM2020-MC weighing machines, our triple deck system, our bucket weigher and or our multihead weigher.

Add-ons to our hardware solutions

As a system integrator, we always want to stay one step ahead of the competition. With products that not only provide better performance, but are also stable, safe and sustainable. This requires optimal maintenance of our installations, easy options for making upgrades and the flexibility to respond quickly and efficiently to changing market requirements. To achieve this, more is needed than good service. View the supplement to our hardware services below.

What our customers in the Agri & Food sector say about us

Want to know more?

Feel free to get in touch – we are more than happy to discuss all the possibilities, together.

Malfunction? Please, contact us

Got a challenge for our Agri & Food team?

Our technical experts are always looking for a new challenge. Has your company encountered problems for which there is currently no solution? Here at ARCO, we are known for delivering innovative, customized solutions.

- Our knowledge is your knowledge

- We never stand still

- Going beyond the best solution

en

en