How our industrial robots work

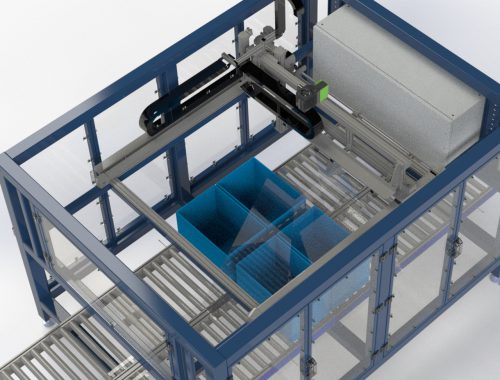

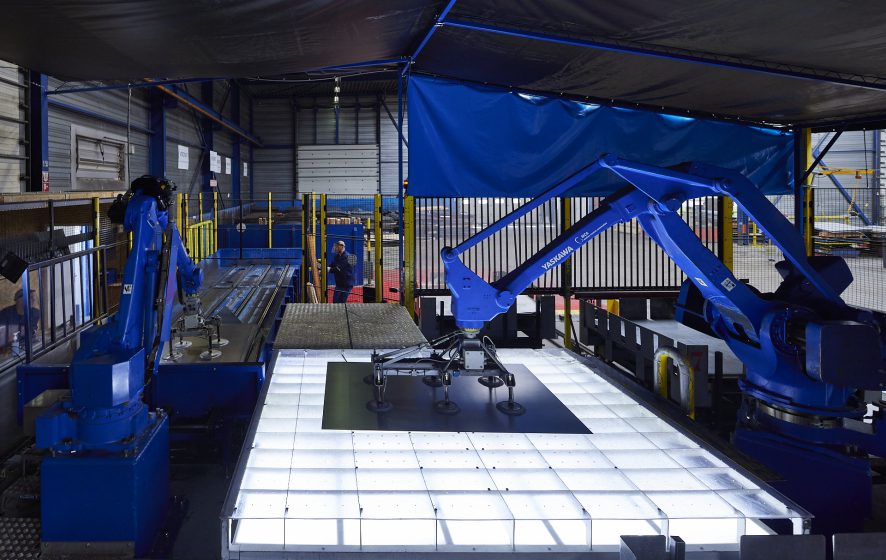

As the industrial robot operates from a single point, this solution is suitable for handling light to heavy products. The industrial robot is highly manoeuvrable and can access everything around its anchor point. Whereas a delta robot can only access products within a circle and is restricted by its three arms, an industrial robot can also reach everything above and below the arm.

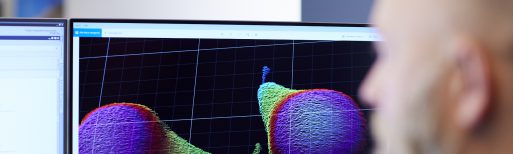

Although it is possible to control an industrial robot manually, it can also be programmed to perform tasks independently. This means that an operator can configure the operations to be performed by an industrial robot beforehand, such as selecting, picking up, and moving desired products. Depending on the purpose of the industrial robot, it can be fitted with a magnet, a gripper hand, or suction cups for example.

Use of our industrial robots

An ARCO industrial robot can be used in all kinds of industries. The possibilities are endless. The industrial robot can be used, for instance, to move, stack, and unstack pallets or to select and move packages with a range of different weights and dimensions. An industrial robot cannot move through the entire room but is dependent upon the pivot point of its arm. This means that the solution is easy to implement in new and existing production lines but it is positioned at one place in the line and cannot be used across the entire line.

Advantages of our industrial robots

An ARCO industrial robot offers the following advantages:

- It can be adapted to the properties of the products being handled;

- It can handle light to heavy products;

- Desired settings can be entered beforehand to enable the industrial robot to work fully automatically;

- It has a reach of 365 degrees from its pivot point;

- As operators no longer have to lift products themselves, they have more time to perform other tasks and they experience fewer ergonomic problems;

- This automated process reduces downtime to a minimum.

Other possibilities

If you need a robot with a greater reach, have a look at our gantry robot. The gantry robot is mounted onto an overhead system, which means that it can move around the entire hall. If you want to sort as many products as possible in the shortest possible timeframe, our ARCO delta robot could be the answer for you. This robotic solution sorts products at high speed. If you are looking for a robot to support and complement the work carried out by your operators, also have a look at our cobot solutions.

Add-ons to our hardware solutions

As a system integrator, we always want to stay one step ahead of the competition. With products that not only provide better performance, but are also stable, safe and sustainable. This requires optimal maintenance of our installations, easy options for making upgrades and the flexibility to respond quickly and efficiently to changing market requirements. To achieve this, more is needed than good service. View the supplement to our hardware services below.

What our customers have to say

Want to know more?

Feel free to get in touch – we are more than happy to discuss all the possibilities, together.

Malfunction? Please, contact us

Our technical experts are always looking for a new challenge. Has your company encountered problems for which there is currently no solution? Here at ARCO, we are known for delivering innovative, customized solutions.

- Our knowledge is your knowledge

- We never stand still

- Going beyond the best solution

en

en