How our Triple Deck System works

With the Triple Deck System, fruits and vegetables are weighed efficiently. Full crates of freshly harvested produce automatically run to the work tables via a roller conveyor. Then the units on the work tables are weighed manually by an operator. The number of operators depends on the product to be processed, as well as on the specific package size and the work rate. After the package is weighed, it is placed on a conveyor belt. The conveyor is divided into two, three or four lines that can move independently of each other. The packages then automatically pass through the Triple Deck System to an inliner, after which the product is ready to be covered (sealed or lidded).

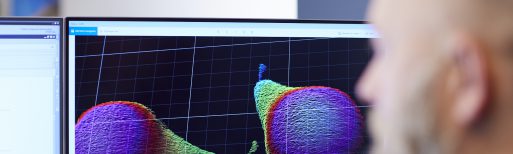

The Triple Deck System can be equipped with a Line Control. With this system very fast product changes can be performed. Connected scales are set to a different recipe at the same time using Line Control. At the same time, performances such as weighing results, operator performance, time and downtime are transparent. Line Control works with an LED indicator and can save 25% in time, compared to a basic scale. An additional benefit is the reduction of give-away. Through automatic software adjustment, no capacity is lost.

en

en