What is predictive maintenance?

Companies use predictive maintenance to carry out maintenance activities at exactly the right time, rather than too early (preventive) or too late (corrective). They use data to predict the best moment to carry out maintenance. Since predictive maintenance is becoming increasingly popular and ARCO likes to be one step ahead of the competition, we are currently working hard to develop this new service.

The benefits of predictive maintenance

The benefits of using ARCO’s predictive maintenance for your installation:

- You can start planning the activities well in advance;

- ARCO can predict, in good time, when your system will fail;

- Components can be replaced just before failures (in accordance with the proposed plan);

- Minimal downtime;

- Maximize the service life of the components.

Reliable predictions based on data

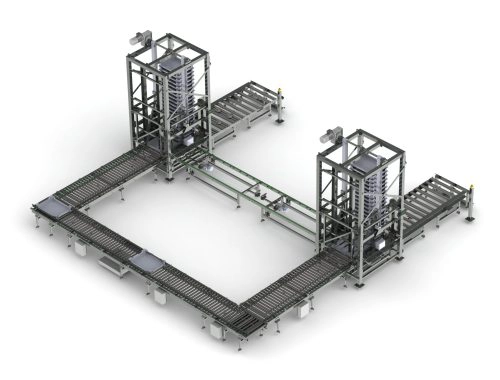

In order to deliver an effective predictive maintenance system for our customers, we have worked hard to

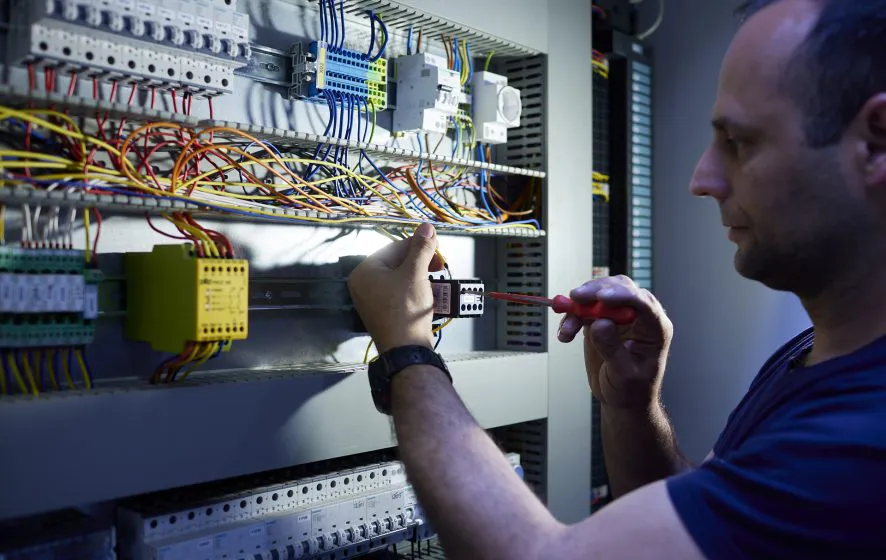

- set up a robust service organization with several service coordinators and several service technicians. Our experts are committed to maintaining machines and processes in the best possible way. Our team of service technicians, who are specialists in the mechanical and software aspects of machines and installations, is available 24 hours a day, seven days a week

- make sure that all our machines and installations can be connected to the Internet. We can connect to the machine or installation remotely via data communication, which gives us access to real-time data. Based on the number of operating hours, for example, it can be determined whether bearings need to be replaced.

Stappenplan voor predictive maintenance

1.Scan the machine

We start by scanning the machine to analyse its components, the estimated service life of these components, and how these components should be cleaned or replaced. This data is then used to create an interactive dashboard, which forms the basis for a plan that is proposed to the customer.

2.Proof of value

Before you adopt a new system, you want to be sure that it will actually benefit your organization. ARCO always offers proof of value; this means that you can test, in real situations, how the system will work for you, where improvements can still be made, and how the system will benefit your company.

3.Implementation

Once the added value of the predictive maintenance system has been proven, we proceed with the implementation of the system. The system is optimized in the proof-of-value phase, after which it can be implemented.

Add-ons to our services

As a system integrator, we always want to stay one step ahead of the competition. With products that not only provide better performance, but are also stable, safe and sustainable. This requires optimal maintenance of our installations, easy options for making upgrades and the flexibility to respond quickly and efficiently to changing market requirements. To achieve this, more is needed than good service. View the supplement to our services below.

What our customers have to say

Want to know more?

Feel free to get in touch – we are more than happy to discuss all the possibilities, together.

Malfunction? Please, contact us

Our technical experts are always looking for a new challenge. Has your company encountered problems for which there is currently no solution? Here at ARCO, we are known for delivering innovative, customized solutions.

- Our knowledge is your knowledge

- We never stand still

- Going beyond the best solution